Victrex has designed two high-performance PEEK polymers, VICTREX CT™100 e CT™200, to offer the cryogenics industry sealing solutions with a broader range of usage and that are suitable for dynamic sealing applications where gases such as LNG (Liquefied Natural Gas) are stored and transported at cryogenic temperatures (-150°C to -200°C).

"What material to use?"

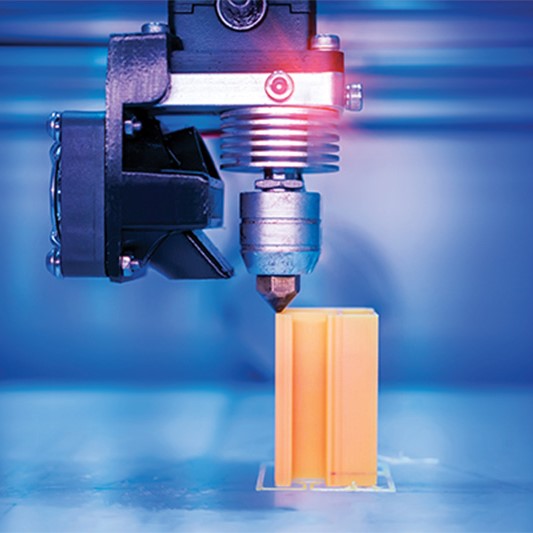

After deciding to rely on 3D printing technology for the production of technical components, this is certainly the first question that could come to your mind.

What is injection molding? What are its benefits and when is it used?

3D printing is not only synonymous with rapid prototyping, production of parts with complex geometries and small series of certified and high-performance pieces. Its potential is even bigger!

Download the new Fluorten Catalogue about Victrex CT™ Polymers

For cryogenic applications, where the engineering requirements are too high for standard polymers, Victrex designed two high-performance PEEK polymers, VICTREX CT™100 and CT™200, and Fluorten took part in the testing process.

From medical technology, mechanical and chemical engineering, to mining, PTFE rotary shaft seals are used in many industries.

We are compliant with the EN 9100:2018 standard (equivalent to AS9100D - JISQ 9100-2016) for the following activities:

- PTFE moulding, extrusion and machining;

- technopolymer injection moulding, 3D printing and machining for the AEROSPACE sector.